Subscribe To Roll-Kraft

Receive the latest news from Roll-Kraft.

Most roll forming machines are equipped with some sort of entry guide or entry table. Their main function is to guide the incoming strip of material into the first pass of forming rolls by setting the elevation and the lateral position of the strip. When properly applied, the entry guide:

Works in conjunction with “traps” in first forming pass to square the strip for the remaining passes

Can be adjusted to shift the strip after threading to alter dimensional features of the product

Can improve results when camber is present in the strip or coil

An improperly aligned entry guide can cause one edge of the strip to ride against one trap on the first forming pass, inducing twist, camber, and burr, as well as dimensional issues in the final product. In an attempt to alleviate these problems, sometimes only one side of the entry guide is used, or in worst cases, both sides of the entry guide are “backed off”. If you are not properly using an entry guide and are plagued by irregularities in profile geometry during a production run, or in achieving repeatable results in multiple runs, consider using it – properly.

Entry guide aligns the strip as it enters the first forming pass

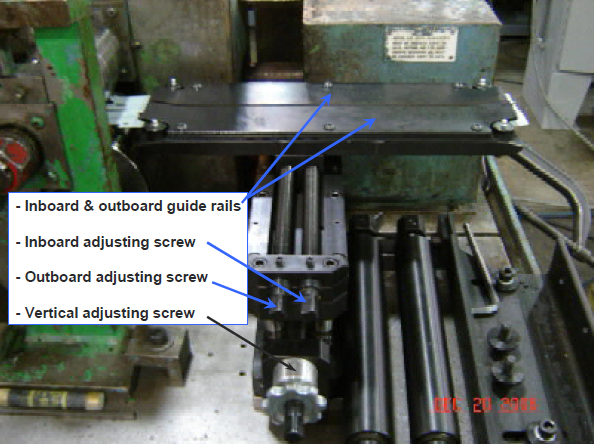

There are many entry table configurations. The majority consist of two adjustable rails that are parallel to each other. Each rail incorporates two or more rollers that are perpendicular to the rolling mill spindles. Many entry tables are vertically adjustable and are set to the elevation of the strip to match the roll tooling. Some entry tables use V-rollers to apply a rounded edge condition to one or both strip edges, while also guiding the strip squarely into the tooling. Normally, hardened rollers or easily replaceable cam followers are ideal. In cases where the strip edges are heavily notched or when cut-to-length strips are fed through the mill, long guide rails with machined ledges are used to hold the strip edges by at least two points at all times.

Note: When pre-cut strips are run through the mill, a flat feed pass with traps should be used (when applicable) in conjunction with the entry table.

Typical features of an entry guide

Checking Guide Rail Alignment

Calibrate the guide rails at regular intervals to maintain parallelism and alignment to the mill spindles. To do this:

Use a straight edge and place against the entry and exit rollers of one of the guide rails

Extend the straight edge through the spindles of the first forming pass

Slide a machined roll onto one of the spindles – making contact with the face and the straight edge

Make necessary guide rail adjustment to allow the straight edge to contact entire roll face

Check and adjust the other guide rail in the same manner

Straight edge being used to check alignment of guide rails

The elevation of the rails should be horizontal to the forming mill (in most cases) and can be checked in a similar manner.

Rest a straight edge against the bottom spindles of the 1st & 2nd mill passes and extend it over the bottom guide rails

Measure the gap between straight edge and guide rail at both entry and exit points

Shim or adjust the guide rails until both measurements are equal

As another option, use a machinist’s level on the guide rail and match to the same level as the mill base

Achieving Repeatable Setups

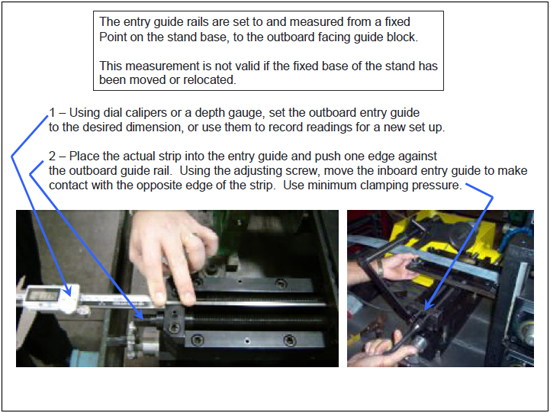

Ideally, the guide rails of an entry table should incorporate digital readouts, locating pins or hard stops for repeatable setups, but many do not. In these cases, some form of measurements can be taken off of a fixed surface of the entry guide base to the outboard guide rail. Once set, the strip from the coil can be used to set the inboard guide rail.

Digital calipers and actual strip used to document and adjust guide rails

After documenting the position of the entry guide rails for a given strip, fabricate some sort of gauge blocks and etch the guide block positions, elevation and the strip width information onto one face (if possible).

While often overlooked, the importance of an entry guide is particularly evident when accuracy is necessary. When considering the benefits of a stable and reliable entry guide, it is well worth the time and attention required to maintain it.

Please contact Roll-Kraft if you would like additional information about entry guides, or any other subject regarding your roll forming operation.

Find more roll forming articles here.

Simply contact us here or call and get answers 24/7.

Contact Us (888) 953-9400

Roll-Kraft is pleased to announce the appointment of Mr. Mike Samplak to the position of Plant Manager at its headquarters facility in Mentor, OH.

Roll-Kraft is pleased to announce the appointment of Frank Lowery to Vice President of Roll Form Applications.

Roll-Kraft is pleased to announce the appointment of Kevin Gehrisch to the position of President.